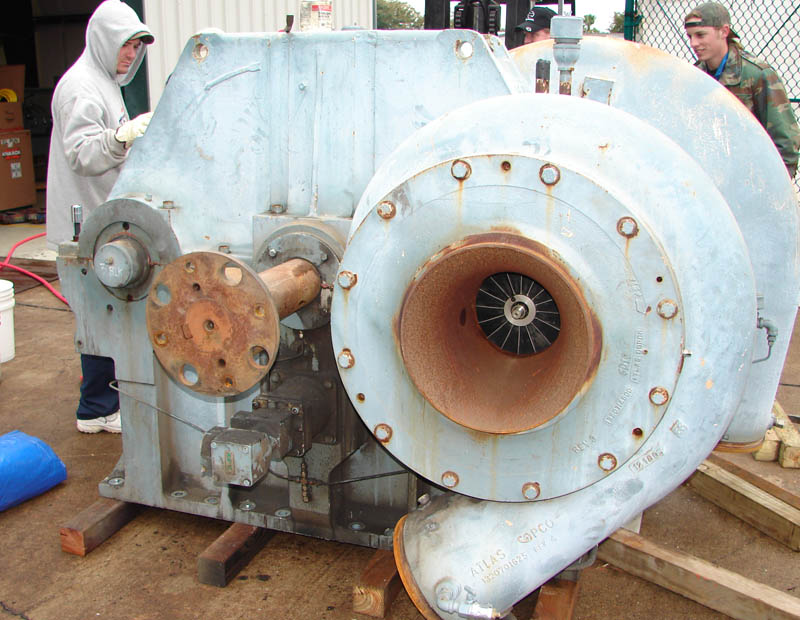

Remanufactured Compressors

Customers rely on us to help them maintain, repair and retrofit all major brands of centrifugal and reciprocating compressors – from 300HP to 30,000HP – in a variety of applications, including carbon dioxide, oxygen, nitrogen, hydrogen and many others. Our repair and manufacturing services, in accordance with API Standards, include the following:

- Complete disassembly and inspection of all components

- RED Process (reverse electrolytic de-rusting) of all components

- N.D.T. and/or Magnetic Particle Inspection of critical components

- Provide process design review, to include;

- Torsional analysis

- Shaking forces study

- Acoustic pulsation studies, including evaluation of pulsation suppression devices and supports considering static loading, acoustical shaking forces and mechanical responses

- Provide pulsation bottle design as well as manufacture the vessels

- Provide piping design as well as manufacture the piping

- Provide intercooler design as well as manufacture the intercoolers

- Provide state-of-the-art redesigned cylinders

- Provide capacity control and/or unloading devices

- Complete divider block lubrication system

- Provide complete vibration protection system

- Installation and commissioning of the compressor

- Supply replacement parts, including valves, pistons, rods, rings, etc.

- Restore used components to original specifications

- Provide field service crews for compressor maintenance or repairs